Don’t see what you need? We can help.

Ask our experts about a custom magnet for your prototype, invention or specialty project.

..to your best source for incredibly strong neodymium rare earth magnets. If you are new to our site, we're glad you found us. We hope we can fill all of your neodymium rare earth magnet needs.

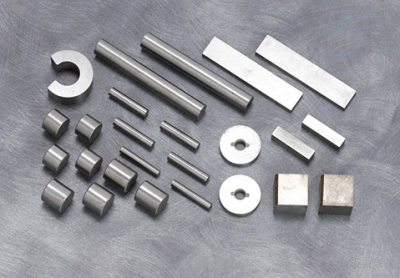

AlNiCo Magnets

These magnets are based mainly on iron (Fe), aluminum (Al), nickel (Ni) and cobalt (Co). The magnets are fragile and not ductile. Therefore, after the raw metal is melted at high temperature and turned into an alloy, it is cast into a casting mold. These magnets are therefore also known as cast magnets.

Al-Ni-Co magnets achieve high Br values and high temperature stability, readily cause low-temperature demagnetization and thermal demagnetization, achieve high mechanical strength, and offer other advantages. However, these magnets have low magnetic coercive force (Hcj) and readily undergo demagnetization due to an external magnetic field, are unsuited for thin products, and placed under other constraints. In the design process, it is therefore important to select a method of magnetization that allows for sufficient shape and magnetic characteristics, and a method of assembly in which consideration is given to demagnetization.

BUILD YOUR CUSTOM MAGNETSSee what tcm magnetics can do for you

Types of Alnico Magnets

Alnico magnets are divided into two types, based on their manufacturing processes.

- Cast alnico

- Sintered alnico

Manufacturing Differences

There are two different manufacturing processes for Alnico:

- Cast alnico may be manufactured in many shapes and sizes not possible with other magnet materials.

- Sintered alnico is usually restricted to smaller sizes and offers slightly lower magnetic properties, but has tighter dimensional tolerances due to its processing.

Advantages

- Wide range of working temperatures, up to 550?

- High field strengths

- Good corrosion resistance

- Can be plated or painted

Disadvantages

- Alnico can easily be demagnetized due its low coercive force.

- Alnico is hard, brittle and unsuited to common drilling, tapping or machining operations.

Applications

- Electric Guitar Pickups

- Motors

- Cow Magnets

- Sensors

- Decentralizers (Oil Field Industry)

- Microphones

- RF Amplifiers (Traveling-wave-tubes)

Surface Treatments

The corrosion resistance of Alnico is considered excellent , and no surface treatments are required. However, Alnico magnets are easily plated for cosmetic reasons if required.

Magnetizing and Handling

Alnico magnets require magnetizing fields of about 3 kOe. Because of their relatively low coercivities, special care should be taken to assure that these magnets are not subjected to adverse repelling fields, since these could partially demagnetize the magnets. Magnetized magnets should be stored with to reduce the possibility of partial demagnetization. If Alnicos are partially demagnetized, they may be easily remagnetized.

The lower coercive force of Alnico makes magnetizing a simple matter in most cases. In order to optimize the performance of Alnico magnets, it is advisable to magnetize the magnet after assembly with other circuit components. This helps control particle contamination, simplifies assembly operations, and helps reduce demagnetization of the Alnico magnet from external influences. These influences can be external demagnetizing fields from other permanent magnets or electromagnets, vibration, and impacts to the Alnico magnet. This material is often supplied with keepers to help ensure the integrity of the magnet or assembly.

Calibration or conditioning of Alnico magnets can also be accomplished after the magnetizing process. During this operation, the Alnico magnets are exposed to a small demagnetizing field or elevated temperatures which partially demagnetizes the magnet. The domains in the Alnico magnet which are influenced are considered weak and they would have demagnetized at some point in the near future. The Alnico magnet conditioning operation essentially demagnetizes the magnet to a stable level which will resist normal magnet aging effects. The usable fields of the resulting magnets are more consistent between magnets and age at a similar rate.

These techniques can be used in large quantities to stabilize a production run, or individually to meet an operational threshold. The individual method is usually employed when a high and low threshold exists for an application.

Custom Ai-Ni-Co magnets